Weeknotes #29

We are very excited about some major updates to Skylark 250 coming later this year - we’ve been working on new connections following the recent round of testing.

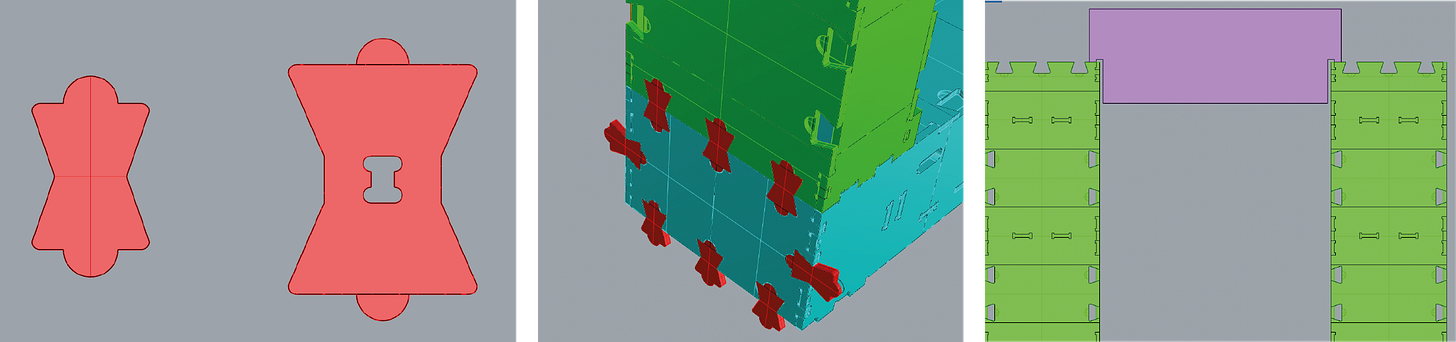

New bow ties and connections - Skylark 0.2

If you have been following us this summer you’ll know we had a round of testing at the University of Strathclyde just last month. We learnt a lot about 250 from our first build and we realised pretty quickly that the original connectors (pegs and combs) we were using could be re-designed for an even easier installation. So we got back to the lab to test a new concept that uses "bow tie" connectors. The latest tensile test showed the connection with 3 bow ties is on average 23% stiffer and 61% stronger than using pegs and combs.

Gabriele, our Engineering Lead, has just finished re-designing the combs and pegs connections into a connection using only bow ties. He’s really been fine-tuning the geometry of the bow-tie shape to optimise the force transfer between the elements, so you end up with a connection that is stronger and stiffer than before. You can see (image 1) that the size of the bow tie has reduced quite a bit, and this also allows us to fit in more bow ties (image 2). Of course, a redesign of the bow tie connectors means that we are having to make major changes to the rest of the blocks. For example you can see (image 3) how the new lintel might work in future.

All this work is ongoing. We have different people on holiday at various points this month so we will continue to work on updating the blocks when everyone is back at work at the end of August.

Engineering guide update

In the last week we have also added a vibration research paper to the engineering guide. Back in May we carried out a vibration test on the floor of our first Skylark project. The main aim was to understand how much beams are working together in transferring the load across the floor. We are grateful to Tom Reynolds from the University of Edinburgh for all his help with this work. You can find the report here.